PRODUCTS & SERVICES

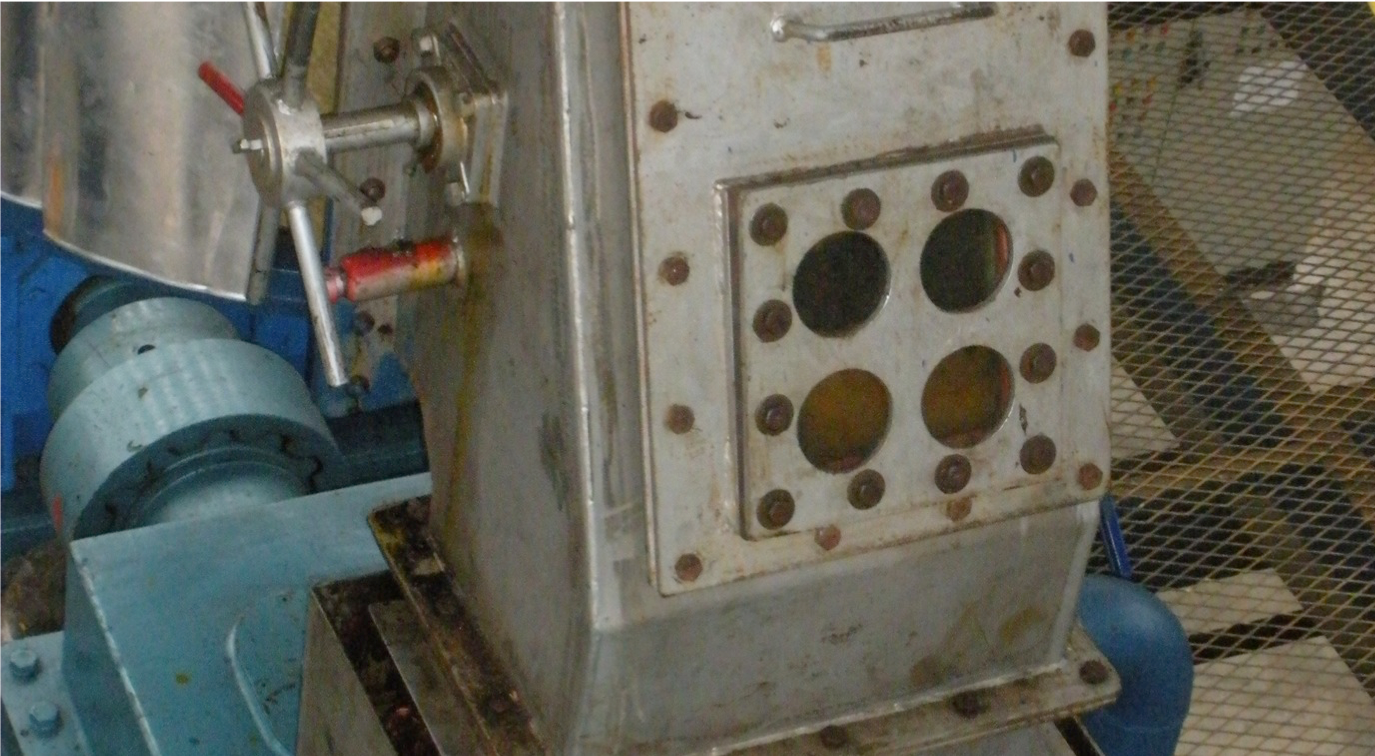

Pressing

The Fruitlets are Received from the Threshers, Softened in Digesters, and then Pressed to Extract the Press Juice which is a Mixture of Crude Palm Oil (CPO), Water, and Solids

- Modern presses use motor driven twin screws and a hydraulic system to maximize sheer of the fruit and extract up to 95 – 97% of the oil found in the fruit.

- Once extracted, the press juice is sent through a vibrating screen to separate the large solid phase from the liquid phase. We offer 60” diameter double deck vibrating screens manufactured by Sweco.

- The extracted CPO is send to the clarification station, while the remaining mixture of fiber and nuts are sent to fiber/nut separation stations.

- Press sizes vary from 10 MT FFB/hr up to 25 MT FFB/hr.

- Digester sizes vary from 3,500 lts/hr to 6,500 lts/hr.

Let’s talk today

Why take chances? We’re there with you all of the way.

+1 786.732.6291

+1 786.732.6291