INTERACTIVE PROCESS

Journey Map

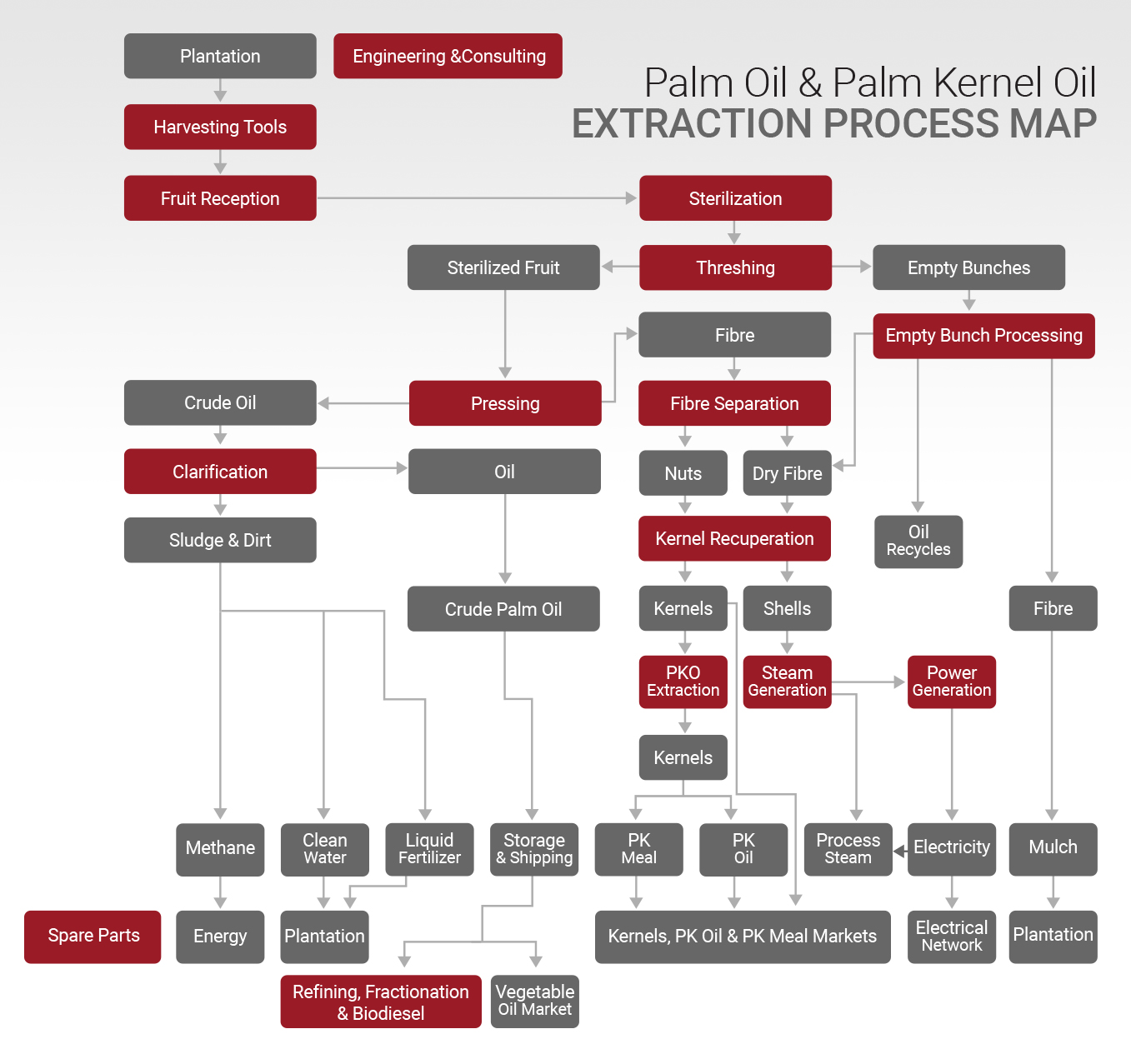

Sterilization

Fresh Fruit Bunches (FFB) Are Cooked In Steam Pressure Vessels – We Offer 3 Types Of Sterilizers

Close

Threshing

The Sterilized FFB Are Tumbled In Drums To Separate The Fruitlets From The Bunch

Close

Empty Bunch Processing

Via Empty Fruit Bunch (EFB) Processing, The Mill Is Able To Convert EFB Waste Into A Revenue And / Or Cost Savings

Close

Pressing

The Fruitlets Are Received From The Threshers, Softened In Digesters, And Then Pressed To Extract The Press Juice Which Is A Mixture Of Crude Palm Oil (CPO), Water, And Solids

Close

Fibre Separation

During Fiber Separation The Fiber And Nut Mixture That Comes Out The Fruit Press Is Separated In A Pneumatic Column

Close

Clarification

The Press & EFB Juice, And Steam Condensate Steam, Is Filtered And Dried

Close

Kernel Separation

In This Stage The Nuts Are Cracked To Obtain The Kernel, Which Is Then Separated From The Shell Of The Nut

Close

PKO Extraction

We Offer Cold Extraction Process To Extract Palm Kernel Oil From Palm Kernel

Close

Steam Generation

Boilers In Palm Oil Mills Use The Biomass Generated In The Process To Produce Steam

Close

Power Generation

The Steam Produced In The Industrial Boiler Can Also Be Used To Power Turbines And Generate Electricity

Close

Spare Parts

Having A Reliable Source For Spare Parts Is Mission Critical To Insure Optimal Mill Performance

Close

Engineering & Consulting

With 100 Years Of Combined Experience In The Industry, We Can Assist You Develop Your Pom Project

Close

Harvesting Tools

We Offer A Selection Of Harvesting Tools Including Knives, Chisels, And Poles

Close

Refining Fractionation & Biodiesel

Through Our Partnership With Climeco International, We Provide Technology To Convert Pome Into Biogas And Renewable Energy

Close

Fruit Reception

Fresh Fruit Bunches (FFB) are Received from the Plantation and Unloaded onto Hoppers

Close

+1 786.732.6291

+1 786.732.6291